Deflection and Curve Rollers Made from High‑Performance Plastics for Efficient Conveyor Technology

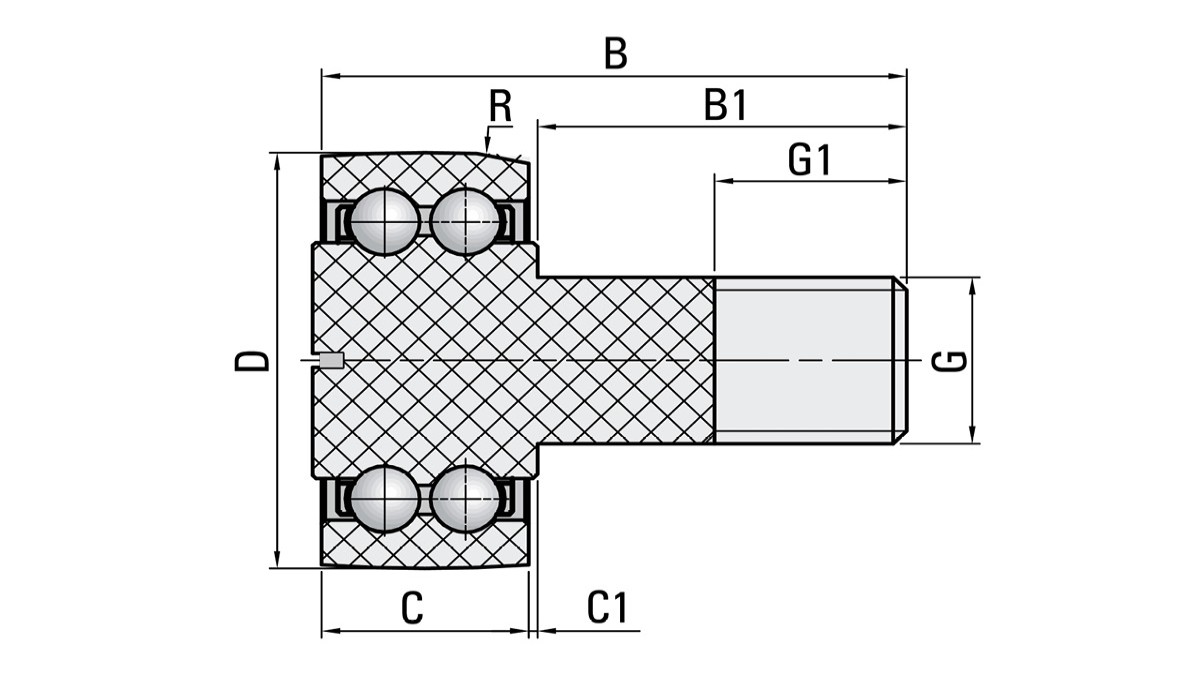

Deflection and curve rollers play a central role in modern conveyor systems. They ensure precise belt guidance, smooth redirection and a reliable material flow – even under demanding operating conditions. Thanks to a wide variety of designs such as single‑, double‑ or multi‑row configurations, different running surface profiles and freely selectable materials, the rollers can be tailored precisely to each application.

Flexible Designs for a Wide Range of Conveyor Systems

Whether used for flat or round belts, compact transport modules or complex conveyor systems, the rollers can be engineered in terms of geometry and material so that they integrate perfectly into the respective machine design. Customized solutions enable more compact assemblies, simplified constructions and an overall more efficient system layout.

Key Advantages of Our Deflection and Curve Rollers

Long Service Life & Reduced Maintenance

Thanks to durable, high‑performance plastics, the rollers are corrosion‑resistant, wear‑optimised and extremely low‑maintenance. This results in long operating life, fewer unplanned stoppages and significantly reduced service requirements.

Resistant to Moisture, Steam and Chemicals

Application‑specific material selections ensure reliable performance even in environments exposed to moisture, cleaning agents or aggressive process media – ideal for conveyor, washing or wet‑processing applications.

Suitable for High‑Temperature Applications

With the right high‑performance plastics, the rollers can be used safely in temperature‑critical environments – up to 250 °C, depending on the chosen material.

Hygienic Solutions for Sensitive Industries

Food‑grade materials make these rollers an excellent choice for the food and packaging industries, where strict hygiene standards and easy‑to‑clean components are essential.

Improved Lateral Guidance

The specialized geometry of our deflection and curve rollers ensures stable and precise belt tracking, particularly in curved sections or at varying transport speeds.

Material Diversity for Optimal Performance

We select plastics specifically tailored to the required properties – whether high temperature resistance, low friction, chemical stability, hygienic suitability or lightweight construction. This targeted material engineering results in durable, efficient and cost‑effective components for a wide range of conveyor applications.

Request Your Project Now

Looking to optimize your conveyor system or need a custom‑designed deflection or curve roller for your application?

Our experts support you from concept to series production – precise, reliable and fast.

Get in touch with us today

and discover how we can make your system design more efficient, more durable and more economical.

Welcome to SMG

You would like detailed information about our product range or technical support.

Please feel free to contact us.

Contact

Schmeing GmbH & Co. KG

Ostring 26

46348 Raesfeld

Germany

Telephone: +49 7431 10 2065

E-Mail:

sales@smg-plastics.de