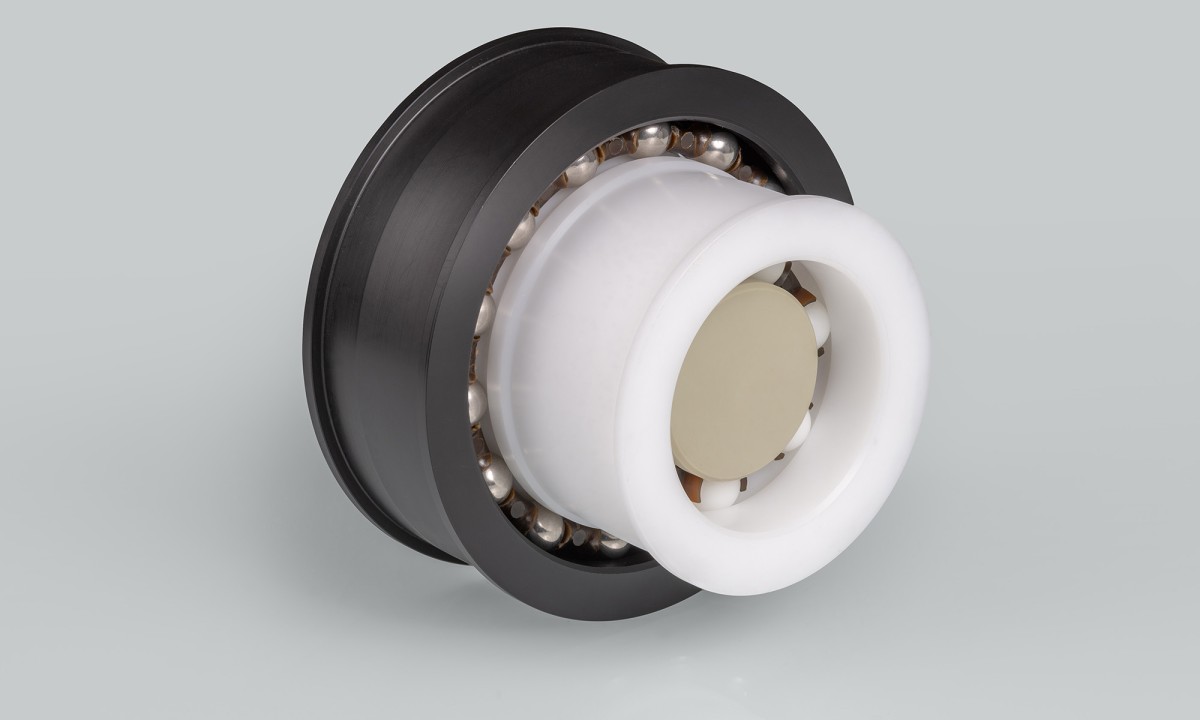

Special roller bearings – Customised roller bearings for the most demanding requirements

SMG designs and manufactures custom rolling bearings that intentionally deviate from standard dimensions, geometries, and materials. Each bearing is engineered individually to meet the exact requirements of your application.

With our deep manufacturing capabilities within the Groz‑Beckert Group, we deliver durable, precise, and high‑performance bearing solutions made from engineering plastics and high‑performance polymers.

What are Custom Rolling Bearings?

Custom rolling bearings are application‑specific components that differ from conventional catalogue bearings. They are used when standard bearings cannot meet technical, environmental, or functional requirements.

SMG offers full flexibility in design, geometry, material selection, and integration of additional functionalities.

What sets SMG special roller bearings apart?

Our customised roller bearings are designed to perfectly suit the respective application – regardless of whether high temperatures, aggressive media, special installation space requirements or additional functions are required.

SMG offers maximum flexibility in design, material and function.

Customisation options

Our customised roller bearings offer a wide range of technical customisation options:

Advanced Material Options

We offer a wide range of engineering and high‑performance plastics tailored to environmental and mechanical conditions:

- Plastics with UV‑stabilizing additives

- High‑performance polymers such as:

- PEEK (Polyetheretherketone) for high temperatures and chemically aggressive environments

- PI (Polyimide) for extreme thermal and mechanical loads

- Materials engineered for:

- Radiation environments

- Chemical exposure

- High‑temperature applications

- Cleanroom or food‑grade environments

Integration of Additional Functional Elements

SMG can integrate functional components directly into the bearing structure:

- Peripheral components incorporated into the outer ring, such as gears or toothed profiles

- Integration of RFID chips for identification, tracking, or maintenance monitoring

- Additional custom components based on customer requirements

Integration of Additional Functional Elements

SMG can integrate functional components directly into the bearing structure:

- Peripheral components incorporated into the outer ring, such as gears or toothed profiles

- Integration of RFID chips for identification, tracking, or maintenance monitoring

- Additional custom components based on customer requirements

Multi‑Row Bearing Designs

For applications requiring higher load capacities, we offer:

- Two‑row and multi‑row ball bearing configurations

- Increased static and dynamic load ratings

Modified Dimensions & Geometries

We manufacture rolling bearings that deviate from standard dimensions, such as:

- Customized inner and outer ring geometries

- Different ring widths (e.g., wider inner ring than outer ring)

- Customized bore or outside diameters

Key Advantages of SMG Custom Bearings

- Tailor‑made for the exact needs of your application

- Integration of additional functional elements possible

- Excellent performance in high‑temperature or chemical environments

- Lightweight, low‑friction, and maintenance‑friendly

- Cost‑efficient through optimized material selection

- High precision and stable quality through manufacturing within the Groz‑Beckert Group

Application Areas

SMG custom rolling bearings are used in a wide range of industries:

- Packaging machinery

- Food and beverage industry

- Medical technology

- Water and fluid management

- General mechanical engineering

- Chemical industry

- High‑temperature or radiation‑exposed environments

Request Your Custom Bearing Solution

We design and manufacture the ideal rolling bearing for your requirements – including geometry, material selection, and optional functional integration.

Welcome to SMG

You would like detailed information about our product range or technical support.

Please feel free to contact us.

Contact

Schmeing GmbH & Co. KG

Ostring 26

46348 Raesfeld

Germany

Telephone: +49 7431 10 2065

E-Mail:

sales@smg-plastics.de