Cylindrical Roller Bearings Made of High‑Performance Plastics – Precise, Durable, Maintenance‑Free

SMG cylindrical roller bearings made of high-performance engineering plastics combine high load capacity with low weight and completely maintenance‑free dry running. Compared to metal bearings or conventional injection‑molded plastic bearings, SMG bearings offer excellent friction behavior, outstanding corrosion resistance, and reliable performance even in challenging environments.

Why Choose SMG Cylindrical Roller Bearings?

- Maintenance‑free operation

- Corrosion‑resistant, even against chemicals

- High radial load capacity

- Lightweight and energy‑efficient

- Low friction and smooth running

- Self‑lubricating, no grease required

- Custom‑engineered design – not standard injection‑molded parts

- Significantly more durable than typical molded plastic bearings

Higher Radial Load Capacity with Cylindrical Rollers

Instead of balls, cylindrical rollers are used as rolling elements, allowing the bearing to handle significantly higher radial loads.

The bearing design consists of an outer ring, inner ring, and cage, providing stable guidance and smooth, low‑vibration operation.

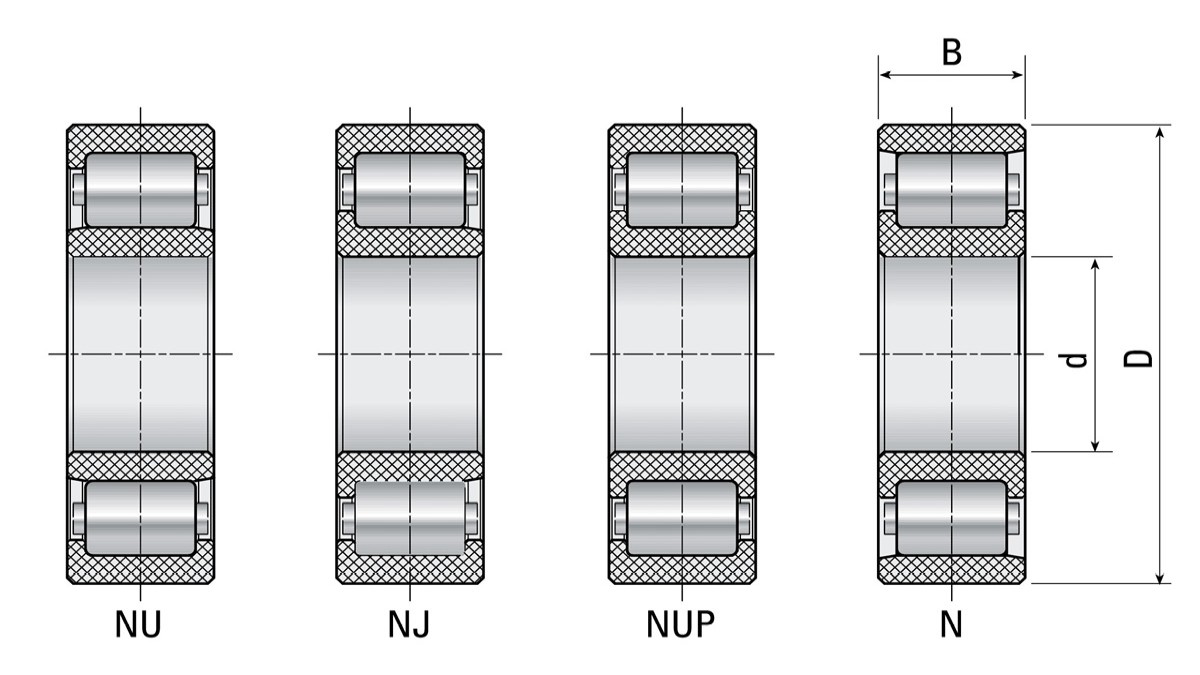

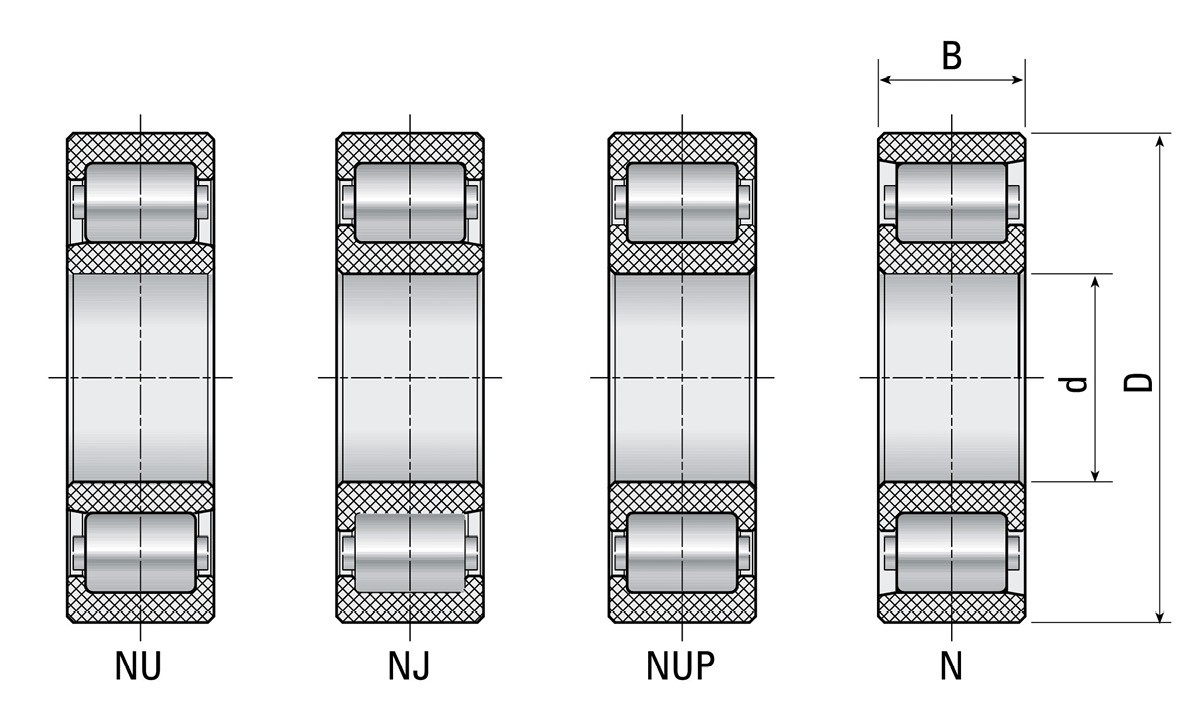

Available Designs: NU, NJ, NUP, and N

SMG plastic cylindrical roller bearings are available in the common industry designs:

- NU

- NJ

- NUP

- N

Thermal expansion of the shaft can be compensated by allowing the rings to move axially,

depending on the design (exception: NUP, which offers axial fixation).

Lubrication‑Free Dry Running – Clean and Reliable

All SMG plastic bearings operate with a maintenance‑free dry running, eliminating the need for oil or grease.

Your benefits:

- zero lubrication, zero maintenance

- clean and hygienic – ideal for food, packaging, pharma, and water treatment

- resistant to moisture, chemicals, and aggressive media

- long lifetime with minimal wear

Custom‑Engineered Bearings – Tailored to Your Application

Every cylindrical roller bearing is individually engineered and manufactured according to your specific requirements.

We adapt:

- material combinations

- load ratings and speed requirements

- dimensional tolerances

- chemical and temperature resistance

- lifetime and wear behavior

To accelerate your development process, we provide a technical specification template

Start Your Bearing Design Today – We Develop the Perfect Solution

Do you have a special application or want to optimize an existing system?

Our engineering team is ready to support you.

Welcome to SMG

You would like detailed information about our product range or technical support.

Please feel free to contact us.

Contact

Schmeing GmbH & Co. KG

Ostring 26

46348 Raesfeld

Germany

Telephone: +49 7431 10 2065

E-Mail:

sales@smg-plastics.de